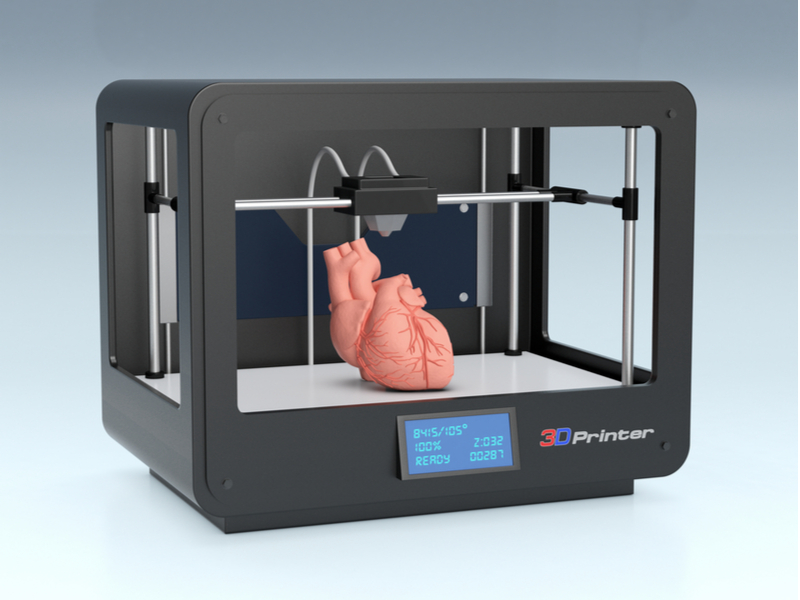

A baby girl in Poland with a missing skull was saved with 3D printing technology, that made her to get back her life.

Giving birth is a natural process and the abnormalities of birth quite happen due to various reasons and cases like missing a part of the body, born with abnormal growth of a part and so, have been in record for years. Such cases are despaired of life by doctors. But to the surprise, technology, engineers and doctors had revived the impossible instance of living, marking a significant feat in the world.

Brain, the complex part of the body, is the challenging organ to handle at times of surgery and if the victim is baby or child, it is arduous. Despite, surgeons in Rzeszow, Poland achieved fixing the 3D printed skull into a baby girl’s head, who was born with a fifth of her skull.

Baby with One-fifth of Brain

A newborn girl in Poland, in a rare case, was born with just one fifth of her skull, without a fully developed occipital bone, that exposed her brain tissue partially. Neonatal surgeries, unlike the adult ones, are delicate and time is a big constrain making every second to count. In account of this, the girl was in the verge of dying in four days (96 hours exactly), if she hadn’t gotten any medical remedy.

Now, Surgeons at the Upper Silesian Centre of child health and doctors imparted the situation to engineers of Warsaw technology 3D printing company called ‘Sygnis’. Sygnis had to 3D-build the exact model of the baby’s skull in one day.

3D Printing the Skull

On the same day of receiving the report to print a skull for saving the baby, the engineers halted every other work in their office and began the process of 3D printing a model of a newborn’s skull using two different technologies simultaneously, hoping that if one fails, another would save.

First model was prepared in SLS Technology (Selective Laser Sintering), which is a powder bed printing technology, that incorporates a laser to fuse tiny bits of nylon powder along the contour to build the shape. The method was realized on a Sinterit Lisa Pro 3D printer from PA 12 powder with an execution time of 24 hours.

The second model involved SLA (stereolithography) technology (printing technology consisting in hardening photosensitive resins layer by layer) – made on a FlashForge Photo 8.9sz 3D printer, standard resin in white. Here the execution time is 8 hours.

The entire project was closed withing 26 hours and the surgeons received the 3D-printed skull, which they successfully operated into the head and the baby girl went home from the hospital.

However, the bones of a child’s skull evolve and undergo constant changes, and hence the girl will have to undergo few more treatments in the future.

3D bioprinting has been made possible when it comes to heart, bone and cartilage, but it’s first of the kind with skull.

Related Posts

3D Printing – Importance

3D printouts have been placed in the archives of the surgical case and are part of the work and practice of a doctor in similar cases. Prof. dr hab. n. med. Łukasz Krakowczyk (the surgeon conducting the operation) emphasized after the successful cooperation that “imaging tests were useful in determining the bone defect of the skull. However, they did not perfectly match the skin defect, which is why the printout of the model was so important. 3D printing will also be indispensable at the stage of reconstruction of the skull bone defect, when it will be necessary to perfectly fit and plan bone reconstruction”.

It’s great to witness how much improved we are in the realm of technology.

(For more such interesting informational, technology and innovation stuffs, keep reading The Inner Detail).