The mini or the thinnest kind of tech looks really cute to use and handle. The reason happens to be the same, of why Apple had been consistent of its mini models. Also, scientifically the lesser the dimensions, more profound the efficiency or endurance. Here, the thinnest loudspeaker ever created awes the world and MIT Researchers whittled the next-generation speaker.

A paper-thin loudspeaker developed by the MIT engineers can turn any surface into an active audio source. The speaker is absolutely as thin as paper, bends to extents, and geometrize to the size of a hand. Avoid doubting the sound quality of the thin-speaker, as it experts in releasing sound with minimal distortion while using a fraction of the energy required by a traditional speaker.

“I think this is a very creative approach to making this class of ultra-thin speakers,” says Ioannis (John) Kymissis

Pioneering simple fabrication technique with just three steps involved, researchers managed to derive this thinness, that it can be sticked inside of an automobile or to wallpaper a room.

How to make the Thinnest Speaker?

A traditional speaker found in headphones or audio system passes electric current through a coil of wire that generates a magnetic field, which moves a speaker membrane that further manipulates the air above it making the sound we hear – a principle related to 12th Physics in India.

Earlier researchers had made thin-film speakers that are designed to be freestanding (which shouldn’t be relied onto something else) and if mounted onto a surface, would impede vibration thereby hampering their ability to generate sound.

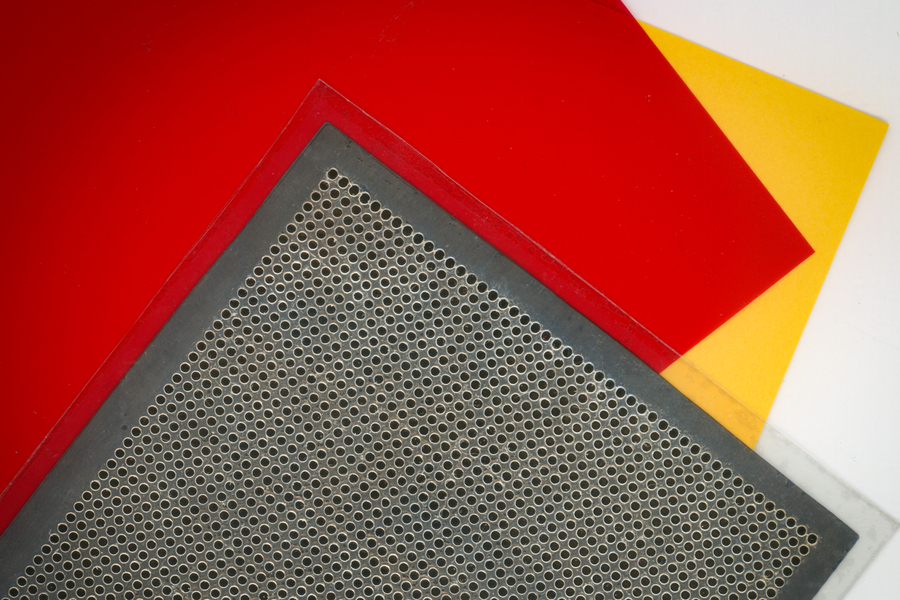

Perhaps, eyeing to this prior-invention, MIT Team renovated the design of a thin-film speaker saturating the already existing problem. Rather than going for an entire film vibrating on magnetic field, their design directs to creation of stacked tiny dome-like bulges on a thin layer of piezoelectric material each capable of vibrating individually. This thin-film is what accounts to the sound and researchers fabricated the film as follows.

Actual making with PET & Piezoelectric material

Researchers cut tiny holes into a thin sheet of PET, a type of lightweight plastic and they laminated the underside of that PET layer with the thin piezoelectric material (8 microns thin) called PVDF. Then they introduced it to a heat source at 800 Celsius, underneath them, after applying vacuum above the bonded sheets.

The heat source caused the ultra-thin piezo film to bulge, reasoning to the pressure difference between vacuum and the source. PVDF on bulging, couldn’t force itself against the PET, except in areas where tiny holes were cut in PET. So, the domes in PVDF protrudes through the holes of PET. The researchers then laminate the other side of the PVDF with another PET layer to act as a spacer between the bulging-domes and the bonding surface.

That’s it! The thinnest speaker is ready…

Related Posts

“This is a very simple, straightforward process. It would allow us to produce these loudspeakers in a high-throughput fashion if we integrate it with a roll-to-roll process in the future. That means it could be fabricated in large amounts, like wallpaper to cover walls, cars, or aircraft interiors,” Hans says.

Experimenting & Results

Researchers then prospected different ways of putting the sizes of holes and domes and proliferated that domes with larger radius displace more air hence produce more sound, but larger domes also have lower resonance frequency, which leads to audio distortion.

The thin-film speaker by mounting it to a wall 30 centimeters from a microphone (to measure the sound pressure level), produced high-quality sound at 66 decibels (conversational levels) when 25 volts of electricity were passed at 1 kHz. At 10 kHz, sound was 86 decibels, same volume as city traffic.

The ultimate energy-efficient thin speaker consumes just 100 milliwatts of power per square meter of speaker, which is about 1/10th of what a typical speaker requires.

Applications

Besides being just a speaker, the peculiarity of the tech enables it to utilize in ultrasound imaging for yielding better resolution of images.

The speaker also manipulated to detect human-detection in a room, by sending waves, just like bats do using echolocation.

If immersed in a liquid, the vibrating membranes could provide a novel method of stirring chemicals, enabling chemical processing techniques that could use less energy than large batch processing methods.

“We have the ability to precisely generate mechanical motion of air by activating a physical surface that is scalable. The options of how to use this technology are limitless,” Vladimir Bulović, director of MIT.nano and senior author of the paper says.

The project currently is funded by the research grant of Ford Motor Company and Lendlease, Inc.

Imagine your wall playing some quality-music for you! Sweet and effortless!