Researchers at MIT have significantly stepped forward on creating robots that could practically and economically assemble or build nearly anything, from vehicles to buildings to large robots, no matter how big the things are.

Scientists and technology have constantly indulged on to reform robots to be a better replacement for humans, making it to think, learn from unconstrained environments like human, work like human and now to a wider extent – to build like humans.

The study from MIT’s Center for Bits and Atoms (CBA), aims for a self-replicating robot assembly system involving swarm of robots that are capable of finishing out complex tasks of building structures larger than itself or constructing larger robots by itself, organizing the work and collaborating as a team to work without crashing into each other physically.

“It could build a structure, or it could build another robot of the same size, or it could build a bigger robot.”

Though this robot-system paves a gap from fully autonomous robot of the kind that can simultaneously plan and work the task given without human intervention, it indeed helps to heed closer to achieve the same.

The new work is reported in the journal Nature Communications Engineering, in a paper by CBA doctoral student Amira Abdel-Rahman, Professor and CBA Director Neil Gershenfeld, and three others.

How this Self-building Robot works?

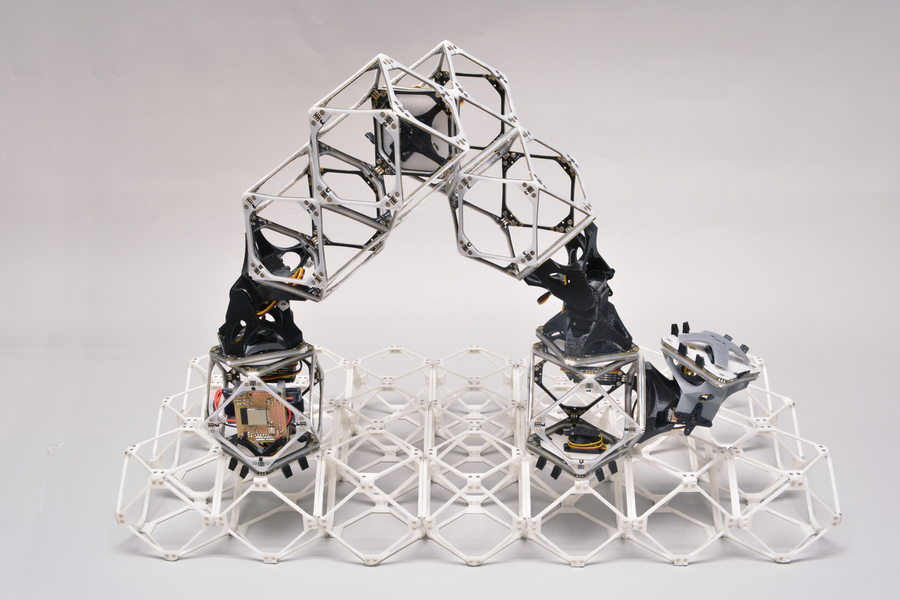

The Self-building robot involves large, usable structures built from an array of tiny identical subunits called voxels (the volumetric equivalent of a 2-D pixel). The identical voxels are interconnected in such a way that it provides a base for robots to stand, pick and build other robots which collectively work as a team to construct what is needed.

Earlier voxels were purely mechanical structural pieces made by plastics and connected by wires to their power source and control systems. But now they had been upgraded to something called ‘complex voxels’ with each individually carrying both power and data from one unit to the next, as well as force.

Meaning, they not only bear loads for robots to build things, but also carry out work such as lifting, moving and manipulation of materials including themselves.

“When we’re building these structures, you have to build in intelligence,” Gershenfeld says.

The robot here is a string of these voxels joined to one-another which can grab another voxel using attachment points & move like an inch-worm to the next desired position where the voxel needs to be attached to grow the structures.

Say, there is a robot-1 which moves independently on the voxels to build another ‘robot-2’, on its own. This robot-1 & robot-2 will eventually proliferate if needed ( if the work is huge) or work together to build something that is assigned. The system allows to accomplish large scale assemblies quickly and the notable aspect here is that the system will themselves decide answers for how many robots to build on their own to carry out the task and what’s the first step to begin with. It’s like robot itself thinking for effective work.

What these Self-building Robots will do?

The team demonstrated how objects such as a deformable airplane wing and a functional racing car could be assembled from tiny identical lightweight pieces – and that robotic devices could be built to carry out some of this assembly work.

The swarm-robotic system might be used to construct a wide variety of large, high-value structures like airplanes, cars and whatever involves big assembly work, besides construction of buildings.

Related Posts

For example, currently the way airplanes are built involves huge factories with gantries much larger than the components they build. “When you make a jumbo jet, you need jumbo jets to carry the parts of the jumbo jet to make it”, Gershenfeld says. “With a system like this built from up from tiny components assembled by tiny robots, the final assemble of the airplane is the only assembly.”

There has been a wide growth in 3D printed houses, which require large machinery, quite bigger than the house itself. Such a kind of large machinery could be swapped with these tiny robots assigned for the same job.

“A home run — [offering] an innovative hardware system, a new way to think about scaling a swarm, and rigorous algorithms,” says Aaron Becker, an associate professor at University of Houston.

And the Defense Advanced Research Projects Agency is also interested in the work for the possibility of building structures for coastal protection against erosion and sea level rise.

It’s hopeful that millennials and Gen-z and then born people could be the first to witness group of small robots building an entire building of tens or even hundreds of feet altitude. Science & Technology is so amazing!