Striving to cope up to these techy days, the construction world has now becoming smart, besides the interior home-appliances. Researchers & scientists are eyeing on upgrading the way of building to a whole astounding level, aiming to provide a self-healing, self-cooling characteristics to its building integrals.

Interesting, isn’t it? If this happens, O-general & Carrier will face a deal-off in the markets.

Future Buildings

If you think buildings will only be made of conventional bricks & concrete, then you should alter your thoughts as constructional manifestations prove that mankind had gradually unknotted the ties of complexities or impossibilities. May it be the Burj Khalifa of Dubai, the tallest of the world, hauling up to 2723 ft, there has been unbelievable structures emerging from the earth.

Now, collaborating with exteriors, interior integrants of the building are also evolving out for characteristic improvement, which happens to be the topic of the page. Those relies on self-healing of cracks on the building, natural self-cooling ability and vitally to trap CO2 in its structure, paving a solution to climate-change, as production of cement, the binding ingredient in concrete, accounted for 7% of global carbon emissions in 2018.

Self-Healing feature of a building

The team from the University of Colorado Boulder are in track to build a fitting self-healing living concrete that would heal its cracks and suck up dangerous toxins from the air.

Scientists have been developing the living concrete by using sand, gel and bacteria. Precisely stating, the photosynthetic microbial bacteria biomineralize with sand-gelatin scaffolds to create living building materials (LBM).

Researchers said this building material has structural load-bearing function, is capable of self-healing and is more environmentally friendly than concrete – which is the second most-consumed material on Earth after water.

For experiments, researchers used cyanobacteria (green bacteria that live in water & can prepare their own food), which absorbs carbon dioxide from the air and make calcium carbonate, the main ingredient in cement.

The microbial viability, i.e., the self-healing characteristic of the concrete is more profound in humid areas. The results showed up for 30 days and microbes are leveraged for self-healing process with three generations from one parent generation.

Self-cooled buildings

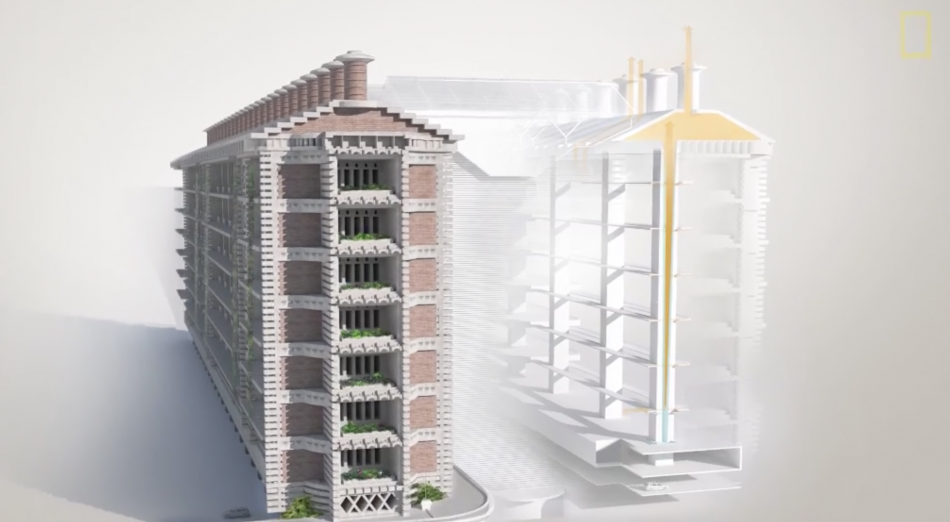

The concept of finding a natural schema of cooling the buildings is actually stolen from termites’ skyscrapers – towers of dirt that can top 30 feet. Spotting some termite mounds on a golf course, dappled with tiny holes, Mick Pearce, a Zimbabwean architect recalled, “I thought, it must be the optimum shape and form for using the natural forces of the climate, and this is where we’ll save a lot of energy”.

Insects’ work, which he refers as metaphoric model, holds chimneys in the top of the mound circulate hot air through its top, while cool air remains in the bottom, where queen hangs out.

Pearce took that idea to his team of engineers, and they incorporated the termite mound design into the new building. The end result is two towers connected by an atrium. At the bottom of each tower is a small arsenal of fans that push cool, ground-level air upward through a series of ducts. That also moves hot air from each floor upward through the building’s chimneys. Pearce used similar termite chimney-inspired designs in a Melbourne office building and a dining hall in Shenzhen, China.

CO2 storing Concrete – a key to resolve Climate Change

Concrete accounts for 7% of global carbon emissions in 2018 and in that 80% of concrete’s carbon footprint comes from cement, one of the aggregates of concrete.

Researchers and companies are focusing on ways to use captured CO2 as an ingredient in the concrete itself, locking it away and preventing it from entering the atmosphere. CO2 can be added in the form of aggregates – or injected during mixing. Carbonation curing, also known as CO2 curing, can also be used after concrete has been cast.

This floating hotel rotates 360-deg to generate electricity for its own use!

These processes turn CO2 from a gas to a mineral, creating solid carbonates that may also improve the strength of concrete. That means structures may need less cement, reducing the amount of related emissions. Companies such as CarbonCure and Solidia have developed technologies to use these processes for concrete poured at construction sites and in precast concrete, such as cinder blocks and other construction materials.

Latest Posts!

- Apple is developing a Brain-Computer Interface for this reason

- 15 Indian Origin Leaders driving AI Revolution in U.S

- What is Gemma 3n AI? How Can you use it with No Internet?

- How to Create Custom GPTs in ChatGPT in just 4 steps?

- 5 Best AI Tools for making Presentations in seconds